- North America:(408) 850-9978

- International:+44 1428 741756

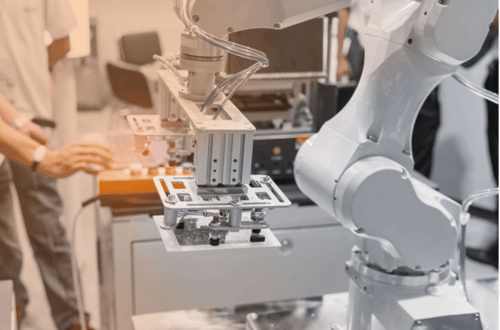

A pioneering global leader in medical device manufacturing faced challenges in optimizing their new manufacturing process for a cutting-edge ultrasound instrument. Due to the range of electronic and mechanical components involved, the assembly of this innovative equipment entailed diverse torque requirements. Initially, assembly workers utilized seven different drivers to accommodate the various specifications. The intricate assembly process also demanded precision in speed, angles, and delicacy of fastener/assembly.

This case study highlights the implementation of a torque control system with one of our esteemed clients, a prominent international medical device manufacturing company. Deployed at a North American facility, the torque tool solution aimed to enhance productivity and refine process control for manufacturing intricate imaging devices, facilitating the transition from development to full-scale production.